What makes ABA 3-layer blown film technology unique?

Symmetric 3-layer structure (A-B-A) enables cost-effective barrier films by sandwiching functional layers (e.g., EVOH) between base layers.

How many temperature zones does YONBANG ABA machine have?

9 independent temperature zones (3 per layer) with ±1°C control accuracy, ensuring precise material processing.

What is the oxygen barrier of YONBANG ABA films for food packaging?

OTR ≤3cc/㎡·day with EVOH middle layer, meeting EU food contact materials regulation (EC 10/2011).

How does ABA structure improve film impact resistance?

50% higher impact strength than mono-layer films, tested at -20°C to +40°C for extreme temperature applications.

Is ABA film production more cost-effective than 5-layer?

30% lower equipment cost than 5-layer lines, with 80% of barrier performance, ideal for mid-range packaging.

What is the typical raw material cost saving with ABA technology?

25-30% savings on expensive functional resins (EVOH, PA) by confining them to the middle layer only.

Does YONBANG provide ABA film recipe development?

Yes, custom recipe development for specific barrier requirements, with 1000+ existing formulations for reference.

What certifications do YONBANG ABA machines have?

CE, ISO 9001, and SGS certification, compliant with safety standards in EU, Americas, and Southeast Asia.

Which industries benefit most from ABA blown films?

Meat/seafood packaging, modified atmosphere packaging (MAP), and agricultural films requiring barrier properties.

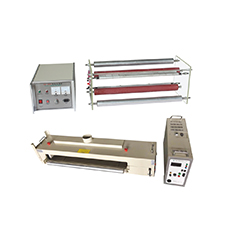

How to test ABA film layer adhesion quality?

YONBANG provides cross-cut adhesion testing (ISO 2409) with ≥4B rating guarantee for layer bonding strength.

What are the main advantages of the ABA structure compared to single-layer films?

The ABA structure offers superior film strength, better thickness uniformity, reduced material cost through core layer optimization, and excellent anti-curling performance - making it ideal for high-quality packaging applications.

What materials are compatible with your blown film machines?

Our machines are engineered to process a broad spectrum of thermoplastic materials, including HDPE, LDPE, LLDPE, and EVA. We also support the processing of biodegradable materials, making our equipment adaptable to sustainable production needs.

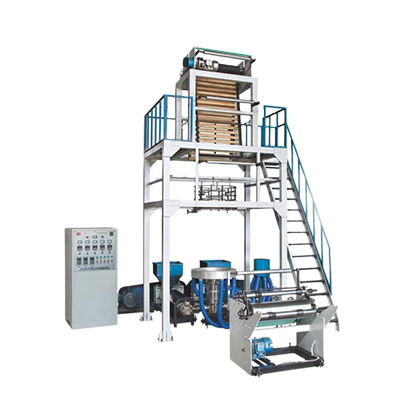

What are the key advantages of your film blowing machines?

Our machines are renowned for three key advantages: 1) Robust Construction for long-term stability and reliability; 2) Intelligent Control Systems for ease of use and superior product quality; and 3) Customization Flexibility to tailor the machine to your exact film production needs, not just a one-size-fits-all solution.

Are your film blowing lines energy-efficient?

Absolutely. Energy efficiency is a core design principle. Our machines feature high-efficiency AC motors, optimized screw designs for lower torque, and advanced IBC (Internal Bubble Cooling) systems that significantly reduce cooling time and overall energy consumption, providing you with a lower cost of operation.