What is the advantage of AB 2-layer blown film technology?

AB structure enables independent control of two materials (e.g., LDPE+LLDPE), improving film toughness by 30% vs mono-layer films.

How does YONBANG AB film machine handle material compatibility?

Precisely controlled temperature zones (160-230°C) support LDPE/HDPE/LLDPE blends, with 2000+ tested material recipes.

What is the maximum film width of YONBANG AB blown film machines?

Up to 3000mm film width, with edge trim ≤3%, ensuring high material utilization for large-scale production.

How accurate is the layer ratio control in AB film machines?

±2% layer ratio precision (e.g., 70% LDPE + 30% LLDPE), critical for consistent barrier properties.

What is the energy consumption of YONBANG AB film machines?

0.8-1.2 kWh/kg film, 18% lower than conventional AB machines, via inverter motor and heat recovery system.

How often do AB blown film machine screws need replacement?

12-18 months service life for alloy screws, 50% longer than standard screws, reducing maintenance costs.

Does YONBANG provide AB film process training?

Yes, 5-day on-site training covering material selection, parameter setting, and troubleshooting for operators.

What is the delivery time for YONBANG AB blown film machines?

45-60 days production + 7-10 days shipping, with expedited options available for urgent orders.

Which industries use AB 2-layer blown films most?

Ideal for heavy-duty packaging (30-80μm), agricultural films, and construction membranes requiring balanced performance.

How to switch between film types on YONBANG AB machines?

Quick mold change design allows material/width switch in 2 hours, supporting flexible production of multiple film types.

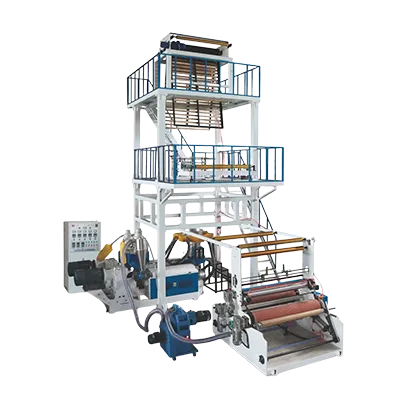

What is an AB double-layer film blowing machine, and what are its main advantages?

An AB double-layer film blowing machine produces two-layer films by combining different polymer materials (A and B layers). Key advantages include enhanced film strength, the ability to reduce material costs by using a less expensive inner layer, and improved sealability or printability on the outer layer—making it a cost-effective upgrade from single-layer films.

What materials are compatible with your blown film machines?

Our machines are engineered to process a broad spectrum of thermoplastic materials, including HDPE, LDPE, LLDPE, and EVA. We also support the processing of biodegradable materials, making our equipment adaptable to sustainable production needs.

What are the key advantages of your film blowing machines?

Our machines are renowned for three key advantages: 1) Robust Construction for long-term stability and reliability; 2) Intelligent Control Systems for ease of use and superior product quality; and 3) Customization Flexibility to tailor the machine to your exact film production needs, not just a one-size-fits-all solution.

Are your film blowing lines energy-efficient?

Absolutely. Energy efficiency is a core design principle. Our machines feature high-efficiency AC motors, optimized screw designs for lower torque, and advanced IBC (Internal Bubble Cooling) systems that significantly reduce cooling time and overall energy consumption, providing you with a lower cost of operation.