Founded in 1998 (formerly Ruian Happy Plastic Machinery), Wenzhou Yongbang Machinery is your reliable partner for high-performance blown film and bag making machines, delivering full-set production solutions from film blowing to bag fabrication.

Backed by nearly 30 years of expertise, we boast a 10-strong R&D team and hold 20+ patented technologies. Our products are certified by BRCGS, FDA, CE, SGS and FSC, with every unit undergoing strict testing to ensure stable, durable performance for heavy-duty operations.

We offer fully customizable machine models for packaging, agriculture and industrial applications, striking a balance between premium quality and competitive pricing to serve businesses of all sizes. Our reliable equipment has reached clients in 40+ countries worldwide, supported by comprehensive after-sales services such as on-site installation, training and prompt spare part supply.

From the scorching deserts of the Middle East to the frigid Siberia, from the rainforests of Southeast Asia to the grasslands of Africa, Yongbang equipment is serving customers in more than 40 countries and regions around the world.

With excellent cost performance and professional localized services, we have become a long-term trusted partner for our international customers.

YONGBANG blown film machines are engineered to handle a comprehensive range of thermoplastic materials, including HDPE, LDPE, LLDPE, EVA, and various biodegradable polymers. For HDPE processing, our standard screw configuration features a compression ratio of 3.5:1 with a length-to-diameter ratio (L/D) of 28:1, optimized for melt homogenization at temperatures between 180-220°C. LDPE processing utilizes a lower compression ratio of 2.8:1 and L/D 25:1 to prevent over-shearing, operating at 160-200°C.

For biodegradable materials like PLA and PBAT blends, we offer specialized screw designs with barrier sections and mixing elements that maintain material integrity at 170-190°C. Our machines achieve consistent layer distribution (±3% thickness variation) across material types, verified through online thickness monitoring systems with 0.5μm resolution. Customers in Peru and Turkey have successfully processed 70% recycled LDPE using our modified feed zones, achieving 98% film clarity compared to virgin material processing (test method: ASTM D1746 haze measurement).

Our extrusion dies undergo a proprietary 5-axis CNC machining process that eliminates traditional manufacturing tolerances. Using DMG MORI DMU 50 machining centers, we achieve positional accuracy of ±0.005mm and repeatability of ±0.002mm across complex die geometries. The 5-axis simultaneous machining capability allows for single-setup production of spiral mandrel dies, reducing cumulative errors from multi-step operations by 85% compared to conventional 3-axis methods.

Critical die components are fabricated from Cr12MoV alloy steel (chemical composition: 1.5% C, 12% Cr, 1% Mo, 0.3% V) which undergoes vacuum heat treatment to 58-60 HRC hardness. Each die is subjected to 100% three-coordinate inspection using Zeiss Contura G2 machines, with inspection points spaced every 2mm along flow channels. Our Turkey flexible packaging clients report 30% reduction in film thickness variation after switching to YONGBANG 5-axis machined dies, as validated by ISO 4593 standard testing.

YONGBANG offers end-to-end customization for extrusion dies, addressing specific customer requirements through a structured engineering process. Starting with material selection, clients can choose between standard Cr12MoV, high-wear D2 tool steel, or corrosion-resistant 420 stainless steel based on their resin type and production volume.

Die geometries are customized using our in-house FEA simulation software, which models melt flow behavior to optimize spiral channel depth (typically 0.8-2.5mm) and land length (15-30mm). For multi-layer applications, we design co-extrusion dies with up to 7 layers, each with independent temperature control zones (±1°C accuracy). Recent projects include a 3-layer biodegradable film die for a Guatemala packaging plant, featuring adjustable layer ratios (10-90%) and automatic profile correction.

Our customization process includes DFM (Design for Manufacturability) reviews within 48 hours of inquiry, followed by 3D CAD approval and prototype machining. All custom dies come with a validation report including pressure drop calculations (ΔP = 6-12 MPa for standard configurations) and shear rate analysis (≤1000 s⁻¹ for shear-sensitive materials).

YONGBANG maintains a rigorous quality control protocol covering all production stages, anchored by our 100% three-coordinate inspection policy for critical components. Each machined part undergoes CMM inspection using a 0.001mm resolution probe, with inspection data stored in a digital quality database for traceability. Our quality management system complies with ISO 9001:2015 standards, with specific controls including:

Raw material inspection: Spectrometric analysis of alloy steel (elements within ±0.05% tolerance) and ultrasonic testing for internal defects

In-process inspection: Statistical Process Control (SPC) with Cpk ≥ 1.33 for critical dimensions

Final assembly: 4-hour continuous run test under 110% load conditions, monitoring vibration (≤0.15mm/s RMS) and temperature rise (≤40°C above ambient)

For exported machines to 40+ countries, we conduct additional testing per regional standards, such as CE compliance for EU markets (EN 60204-1 safety requirements) and UL certification for North America. Our Russia clients have validated that our quality control processes result in a Mean Time Between Failures (MTBF) of 16,500 hours for extrusion systems, calculated using the formula: MTBF = Σ(operating hours) ÷ number of failures over 3 years of field data.

YONGBANG's bimetallic barrels feature a proprietary centrifugal casting process that bonds a 2.5mm thick wear-resistant alloy layer (composition: 28% Cr, 5% Mo, 1.5% Ni) to a carbon steel substrate. This construction achieves a hardness of 62-65 HRC on the inner surface, while maintaining the structural integrity of the base material. Comparative wear testing against standard barrels shows our bimetallic solution reduces wear rate to 0.03mm/1000 operating hours, compared to 0.1mm/1000 hours for conventional nitrided barrels.

The barrels are designed with optimized cooling channels (diameter 8mm, spacing 30mm) to ensure uniform temperature distribution (±2°C across barrel length). Thermal expansion calculations (ΔL = αL₀ΔT) are performed during design to maintain precise clearance between screw and barrel (0.3-0.5mm for standard applications). A Turkey plastic factory operating our bimetallic barrel system continuously for 12,000 hours reported only 0.08mm wear, extending service life to 10+ years under typical operating conditions.

We provide specialized technical solutions for biodegradable material processing, addressing the unique challenges of polymers like PLA, PBAT, and starch-based blends. Our technical package includes:

Material-specific screw designs with low-shear mixing sections to prevent thermal degradation (maximum shear rate < 800 s⁻¹)

Temperature profiling systems with 5-point monitoring (feed zone: 60-80°C, compression zone: 160-175°C, metering zone: 170-185°C)

Die lip cooling modifications to handle the lower melt strength of biodegradable resins

Process optimization guide with recommended blow-up ratios (1.8-2.2:1) and haul-off speeds (30-60 m/min)

Our R&D team has developed a biodegradable processing calculator that predicts optimal parameters based on material composition. For example, when processing 70% PLA/30% PBAT blends, the calculator recommends a screw speed of 45-55 RPM and die gap of 0.8mm to achieve 20μm film thickness with ±5% tolerance. We offer on-site testing services at our facility, with a dedicated 5-layer blown film line for customer material trials, typically completed within 5-7 business days.

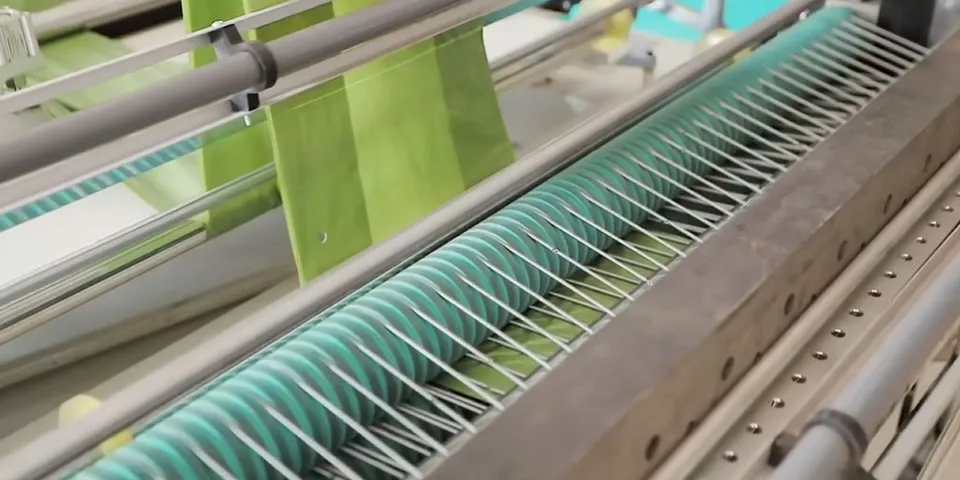

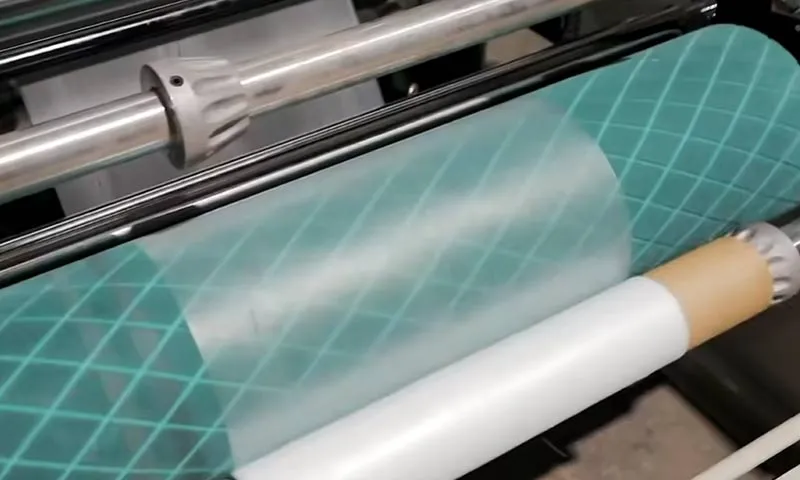

YONGBANG multi-layer co-extrusion systems incorporate advanced technologies to maintain precise layer control and uniformity. Our feedblock designs utilize flow simulation software to calculate channel dimensions, ensuring each layer's flow rate matches the target ratio (±2% deviation). The dies feature adjustable choker bars with micrometer controls (0.01mm resolution) for on-the-fly thickness correction.

Each extrusion station is equipped with a separate AC servo motor drive system, providing independent speed control (±0.1 RPM accuracy) for different material viscosities. In-line monitoring includes an infrared thickness gauge with 50 measurement points across the film web, sampling at 100Hz to detect variations as small as 0.1μm.

For a Mexico customer producing 5-layer barrier films, we implemented a closed-loop control system that maintains layer ratios within 1% of setpoints, verified by ASTM D374 standard thickness testing. The system includes automatic profile correction that adjusts die lip temperature zones (±0.5°C precision) to compensate for material viscosity changes during production runs exceeding 8 hours.

Standard lead times for YONGBANG custom extrusion tooling range from 4-6 weeks for dies and 6-8 weeks for complete extrusion systems, with expedited options available for critical projects. The timeline breakdown includes:

Engineering and design: 5-7 days (including FEA analysis and customer approval)

Material procurement: 3-5 days for standard alloys; 10-14 days for specialty materials

Machining: 10-15 days for dies; 20-25 days for complete systems

Quality inspection and testing: 3-5 days

Packaging and shipping: 2-5 days (depending on destination)

Lead times may extend for highly complex designs (e.g., 7-layer co-extrusion dies with automatic gauge control) or when utilizing specialized materials like Hastelloy for corrosive applications. We maintain a raw material inventory of Cr12MoV and D2 tool steel to reduce procurement time by 30%. For urgent orders, we offer a priority production service that accelerates delivery by 40% with a 25% expediting fee. Our Turkey and Russia clients typically receive standard dies within 5 weeks from order confirmation, with 98% on-time delivery rate over the past 3 years.

YONGBANG provides comprehensive after-sales support to our 40+ export markets through a structured service program. Each machine shipment includes a detailed technical manual with 3D exploded views, maintenance schedules, and troubleshooting flowcharts. Our global service network includes 12 regional support centers with factory-trained technicians, offering:

24/7 technical hotline support with average response time < 2 hours

On-site installation and commissioning (typically 3-5 days for standard lines)

Operator training programs (5-day intensive courses covering setup, operation, and maintenance)

Preventive maintenance kits with recommended spare parts清单 based on 10,000-hour operation data

Remote diagnostic capabilities via machine-mounted IoT sensors (optional)

We calculate maintenance intervals using the formula: T = (MTBF × 0.7) where MTBF (Mean Time Between Failures) is 16,500 hours for our extrusion systems. Critical components like screws and barrels have a 12-month warranty, with extended warranty options up to 3 years. A Peru fishing company recently utilized our remote diagnostics to resolve a temperature control issue, avoiding a service visit and reducing downtime to 4 hours compared to the industry average of 48 hours for similar problems.

YONGBANG's 5-axis CNC machining centers (DMG MORI DMU 50) enable production of extrusion tools with complex geometries that traditional machining cannot achieve. The simultaneous 5-axis movement allows for continuous machining of contoured surfaces, eliminating the need for multiple setups and reducing positional errors by 85%. This technology is particularly advantageous for:

Spiral mandrel dies with variable channel depths (0.8-2.5mm) and constant pitch angles (15-20°)

Feedblocks with streamlined flow paths that reduce pressure drop by 15% compared to conventionally machined designs

Complex die lips with micro-groove cooling channels (0.5mm width) for precise temperature control

Our 5-axis machining process achieves surface finishes of Ra 0.4μm on die flow surfaces, reducing resin flow resistance and improving melt distribution. Tooling produced using this method shows 30% better flow uniformity compared to 3-axis machined tools, as measured by pressure mapping tests (±5% pressure variation across die width). A Turkey automotive film manufacturer reported 22% reduction in scrap rates after implementing our 5-axis machined dies, due to improved gauge control and reduced uneven thickness.