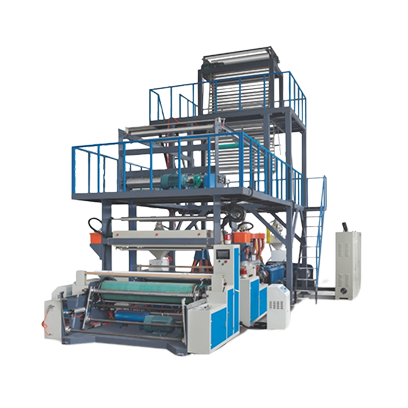

Our premium ABC series is designed for high-performance 3-layer asymmetric films (A/B/C). It enables the precise combination of three different materials, allowing each layer to be optimized for a specific function like sealing, strength, and barrier protection. This is the ultimate solution for demanding packaging applications.

Let us provide you with the products that best suit your needs.

YB series three-layer co-extrusion blown film machine produces high-performance films using different polymer combinations, offering both premium quality and cost efficiency for specialized applications.

We provide end-to-end professional support to secure production stability and foster your business development, from selection to daily operation.