What is YONBANG's quality control process?

5-stage QC: raw material inspection → component testing → assembly verification → 72-hour run test → final calibration.

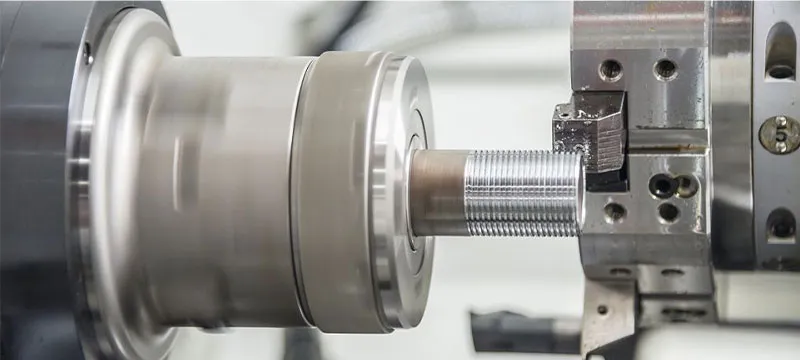

How precise is component manufacturing?

CNC machining with ±0.02mm tolerance, 100% inspected via coordinate measuring machines (CMM).

What is the 72-hour run test protocol?

Continuous production at 80% load with real-time monitoring of temperature, vibration, and output stability.

How are critical components like screws tested?

100,000-cycle fatigue test, hardness testing (HRC 58-62), and wear resistance verification.

What quality certifications does YONBANG hold?

ISO 9001, CE, SGS, and FDA compliance for food contact materials in machinery components.

Is there full material traceability?

Yes, batch-level material certification with 10-year record retention, compliant with EU REACH regulations.

How does YONBANG use data for quality improvement?

AI-driven quality analytics from 40+ countries of field data to identify and prevent potential issues.

What is the customer complaint resolution rate?

98% resolution within 72 hours, with root cause analysis and preventive actions documented.

How does YONBANG QC compare to industry standards?

30% stricter tolerance controls, 2x longer endurance testing, and 100% inspection vs industry sampling methods.

How to audit YONBANG quality system?

Pre-audit documentation package and on-site quality system audits by customer's third-party inspectors.

Are your machines suitable for producing export-quality products?

Yes. Our equipment helps customers meet international packaging and product standards, including FDA-compliant food-grade films and biodegradable material requirements.

Can you provide customized solutions while maintaining quality?

Absolutely. Customized machines follow the same strict quality control procedures as standard models, including design review, prototype testing, and final validation according to client requirements.

Are your film blowing lines energy-efficient?

Absolutely. Energy efficiency is a core design principle. Our machines feature high-efficiency AC motors, optimized screw designs for lower torque, and advanced IBC (Internal Bubble Cooling) systems that significantly reduce cooling time and overall energy consumption, providing you with a lower cost of operation.